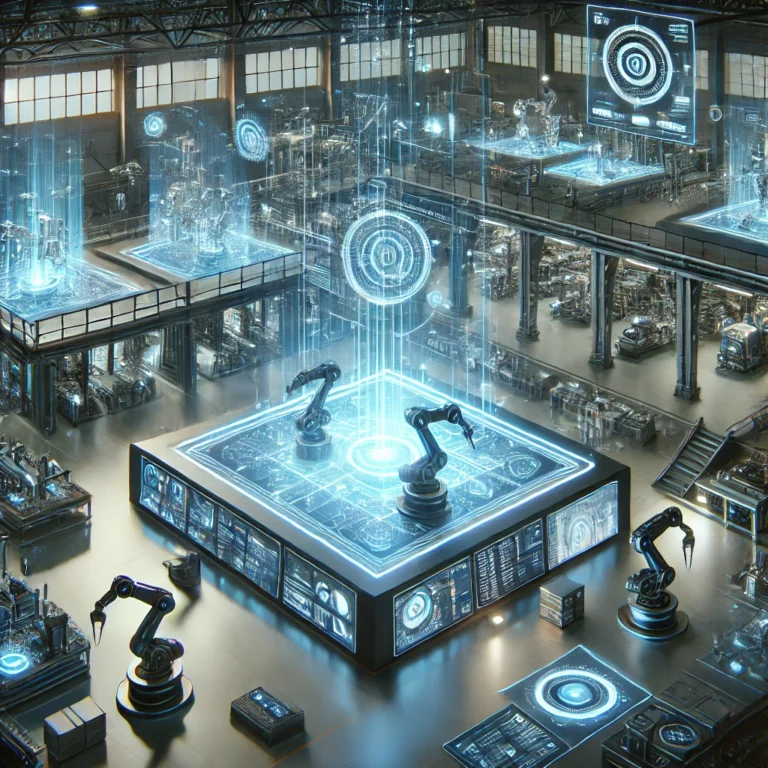

Flexibility is at the Heart of Industry 4.0

Industry 4.0 has redefined production by placing adaptability and speed at the core of manufacturing. Businesses can no longer focus solely on efficiency—they must also respond rapidly to changing demands. This is where digital twin technology steps in, enabling the foundation of flexible and intelligent production systems. With its advanced solutions, TwinUp empowers production lines with agility, real-time data integration, and strategic control.

What is a Digital Twin and Why is It Critical?

A digital twin is a dynamic digital replica of a physical object, process, or system. It receives real-time data from sensors and mirrors real-world operations. Businesses can not only monitor the current state of their production but also simulate scenarios, make better decisions, and minimize risks before implementation.

What Does a Flexible Manufacturing System Offer?

Flexible manufacturing refers to the ability to quickly adapt to different product types or demand changes. Through such systems, businesses:

- Easily switch between product models,

- Respond rapidly to fluctuating customer needs,

- Maximize resource efficiency.

TwinUp analyzes and simulates these transitions digitally, helping businesses restructure their lines for optimal performance.

How Do Digital Twins Enhance Flexibility?

Whenever changes are planned in the production line, TwinUp first simulates them digitally. Managers can:

- Visualize outcomes without taking risks,

- Make faster and more informed decisions,

- Optimize every step of the production process.

Its AI-supported infrastructure ensures decisions are always backed by data.

Instant Adaptation Through Real-Time Data

The TwinUp digital twin system processes live data from the production line. It constantly:

- Monitors line performance,

- Detects bottlenecks in advance,

- Suggests quick and effective improvements.

This creates a proactive—not just reactive—manufacturing ecosystem.

Proactive Maintenance for Continuous Production

Digital twins cover not only production but also equipment. TwinUp improves maintenance processes by making them smarter and more planned. Companies can:

- Predict malfunctions in advance,

- Act timely without interrupting production,

- Keep machines running at peak efficiency.

This approach minimizes downtime and increases operational continuity.

Build the Factory of the Future with TwinUp

TwinUp guides companies in their digital transformation journey. We:

- Create digital twins of your production systems,

- Continuously analyze and improve them,

- Help you build sustainable, agile, and future-ready operations.

The factories of tomorrow are already possible today—with TwinUp, you can lead the way.